Find out how to transform

the global problem of plastic waste

into a highly profitable eco-friendly business

There are huge amounts of plastic produced in a modern world

becoming tons of garbage that will be inherited by future generations.

More than 3 billion tonnes of household and industrial waste is generated globally each year, including one of the most environmentally-hazardous varieties of plastic. This pollution is a result of human economic activity.

Every year, the volume of plastic waste is actively increasing. This causes irreparable harm to the environment and is contributing to mass global warming.

OF PLASTIC HAS BEEN CREATED BY HUMANITY SINCE 1950

OF PLASTIC HAS ALREADY BECOME GARBAGE NOW

IS THE TIME IT TAKES FOR PLASTIC TO FULLY DECOMPOSE

By 2050, the amount of plastic in the world's oceans will exceed the number of its inhabitants according to the UN

More than 30% of plastic waste is dumped unregulated on the land and in the world’s oceans right now.

This volume is the equivalent to the contents of one garbage truck, filled to the brim with plastic waste, being poured into rivers and seas every minute.

How does the world recycle plastic waste today?

Recycling is the only effective way to keep plastic out of landfills and reduce environmental issues. However, modern recycling systems are lagging behind the huge volume of plastic waste. Over 90% of plastic is transported to landfills, incinerators, and the countryside in Russia. One of the highest recycling rates in the world, in terms of the volume of collected waste, is Germany. But in Russia, only 38% of plastic waste is sent for recycling

- Waste recycling

- Garbage incineration

- Landfill collection

- uncontrolled waste disposal

- Waste recycling

- Incineration of waste

Why does Germany burn over 60% of plastic?

31% of plastic waste collected in 2016 is registered as ‘recycled’, according to statistics for the EU, as a whole. Most of this volume was exported to low-income countries and the ultimate fate of the waste was unknown. China banned the import of foreign waste In 2018 and the export of plastic waste worldwide fell by 50%. The plastic waste collected for recycling has begun to accumulate or be disposed of in the wrong way.

Why is plastic recycling difficult?

Polymers have many layers

Disposal requires sorting waste. Many polymers are thermodynamically incompatible.

High toxicity

Hazardous substances are released during the processing of polymers, such as nitrogen dioxide, and formaldehyde.

Low profitability

The relatively high complexity and low profitability of some of the processing methods

Problem

Humanity is trying to solve the issue of plastic recycling but has so far stopped at the process of plastic consolidation, in search of a further solution.

IKHLYAS has developed a turnkey solution

Since 2006

IKHTECH has been running a unique plastic waste recycling plant.

We have developed and patented this advanced technology for the utilisation of non-recyclable polymers, with the parallel production of alternative motor fuels in the form of additives, gas and carbonaceous sludge.

The main advantage of the technology is its ability to efficiently and sustainably process plastic waste.

Technology features

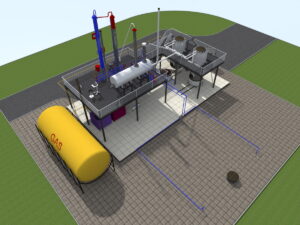

The IKHTECH Unit is designed to thermally destruct polymer waste using a catalyst in a sealed container. This makes it possible to divide the gas stream, with further condensation, into fractions (gas, liquid, and solid) rapidly and efficiently. It separates plastic waste into five fractions in one recycling process, without additional distillation.

Plastic waste

The amount of waste that’s produced by one tonne of polymers.

Diesel additive

For diesel engines — complies with Euro 4 and Euro 5 standards

Gasoline additive

For gasoline engines — complies with Euro 4 and Euro 5 standards

Gas

Can be used for the production process or the generation of electricity

Paraffin

Has many industrial and everyday uses (production of candles, matches, etc.)

Carbon residue

Can be used in road construction and the production of dyes

There are no analogues in the world

Competitive advantages of IKHTECH plastic recycling plants

High performance

1 litre of processed products are produced from 1 kilogram of raw plastic waste: gasoline and diesel additives, gas, carbon residue, and paraffin.

Complete recycling of polymers

No adverse effect on the environment, as opposed to waste treatment plants, and the flue gas temperature does not exceed 100 degrees.

High product quality

Gasoline and diesel additives comply with Euro 4 and Euro 5 standards. Other processed products do not contain impurities of lead, sulfur, and other metals.

Energy autonomy

The IKHTECH unit consumes less than 5 kilowatts of electricity and is capable of self-sufficiency using electric generators.

Circuit and compact equipment

IKHTECH Unit can be situated in a small area, even within the city. The plant has a high degree of safety due to the lack of pressure during waste processing.

Highly profitable production

The payback period is from one year. You will also receive government financial support for the complete and safe disposal of plastic waste.

Choose a suitable IKHTECH Unit

IKHTECH 5

productivity per day

diesel additive

gasoline additive

paraffin

synthetic gas

carbon residue

required area

energy consumption

water consumption

generate electricity

IKHTECH 10

productivity per day

diesel additive

gasoline additive

paraffin

synthetic gas

carbon residue

required area

energy consumption

water consumption

generate electricity

IKHTECH 30

productivity per day

diesel additive

gasoline additive

paraffin

synthetic gas

carbon residue

required area

energy consumption

water consumption

generate electricity

Return on investment

The amount of raw materials for IKHTECH plants is enough for all over the world now!

Growing global demand for consumer goods is driving a proportional increase in plastic waste, despite the launch of various polyethene recycling programs.

150 million tonnes of waste was produced in 2004, by 2019. Since then, this figure has doubled and already exceeds 300 million tonnes, which has become a direct threat to the global ecosystem.

The volume of plastic waste in the world

million tons

Plastic waste codes that we recycle

Let's help ecology together

The technology for the thermal destruction of plastic waste, developed by IKHLYAS TECHNOLOGY, solves several significant environmental problems at once.

No harmful fumes

— unlike incinerators, with their toxic emissions into the atmosphere

Full autonomy

— due to the production and accumulation of gas in the power generators during disposal

Reduces the load on solid-waste landfill

This is achieved by recycling large volumes of plastic waste

Recycles raw materials 100%

1 litre of useful recycled products produced from 1 kilogram of plastic waste

Protects the environment

— in the region where the IKHTECH equipment is installed

Completely safe

The IKHTECH Unit is equipped with a fire extinguishing system using water vapour